Why PENGI fiber best for making outdoor weighted curtains?

Oct 18,2023 | snowcityshop

What is PENGI fiber?

In the textile market, PENGI occupies a leading position in the field of outdoor decoration (including not only awnings, but also general outdoor products ranging from sun umbrellas to sun beds, upholstery, car canopies, boat covers, and other items used for outdoor activities). Currently, the three most commonly used production methods for PENGI are the pre-spinning stock coloring method, wet tow dyeing (i.e., gel dyeing method), and continuous dyeing of filament tows.

Features of Outdoor Textiles

Because of its outstanding sun and weather resistance, pengi's original field of application was in the production of fabrics for outdoor use. Outdoor textiles with practicality must meet the following requirements:

1. Excellent sunlight resistance and weather resistance, unaffected by the environment;

2. High strength, mildew resistant and non-corrosive;

3. Bright color with high color fastness to sunlight.

In recent years, due to the expanding usage of PENGI in the outdoor application market, especially in developed countries, pengi has further developed.

(PICTURE 1)

.jpeg?w=700&h=600)

(PICTURE 2)

PENGI's general dyeing process such as loose fiber dyeing, yarn dyeing fabric dyeing, and even gel dyeing can not meet these basic requirements, so there is PENGI's original coloring method.

There are various ways to talk about the original liquid-colored acrylic fiber, such as Solution-dyed acrylic fiber, pigmented-dyed acrylic fiber, mass-dyed acrylic fiber, and so on.

(click the picture for the shop)

PENGI fabric vs. cotton

When synthetic fibers first appeared on the market, outdoor products were mainly made of cotton. Among the various synthetic fibers acrylic, nylon, polyester, and polypropylene, pengi is fast growing as the most suitable fiber for outdoor use. This is due to the fact that PENGI has the following characteristics compared to cotton:

1. Excellent vividness and highest color fastness;

2. Higher light resistance (thus having a longer life cycle);

3. Very good performance-price ratio.

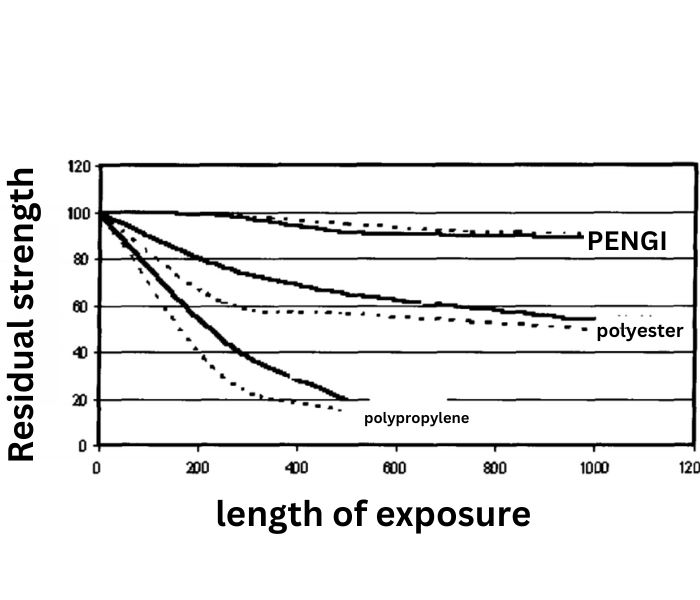

With great success, pengi manufacturers have developed specialty fibers for different outdoor applications. The main difference between this fiber and cotton and polyester is the excellent properties of PENGI itself. PENGI already has these properties, although cotton and polyester require finishing on woven fabrics to provide the necessary light and weather fastness. PENGI, polyester, and acrylic sunlight fastness to artificial light are shown in the graph, and a comparison of the weather-fastness of PENGI and cotton fabrics is shown in the graph.

Therefore, for pengi fabrics, it is no longer necessary to carry out the same finishing as cotton and polyester, which can affect the performance and quality of the fabric.

(click the picture for the shop)

Advantages of PENGI

Pengi has very high color fastness. Generally speaking, according to the application, Pengi is basically divided into two categories: land-use liquid-colored acrylics and water-use liquid-colored acrylics.

Colorfastness requirements for land-based PENGI

After irradiation with light under controlled conditions, the color difference should be less than 5 DeCMC when measured by an ULTRA SCAN XE spectrophotometer with a xenon lamp.

(click the picture for the shop)

Colorfastness requirements for Water PENGI

The color difference should be less than 5 DeCMC when measured by ULTRA SCAN XE spectrophotometer with xenon lamp after irradiation with UVA340 etc. under controlled conditions.

After only 1000 h of irradiation, the strength and elongation values of awnings made from polyester filaments decreased to less than 50%, but the strength and elongation of awnings made from pengi did not show significant changes.

Stress-strain curves of polypropylene awnings and PENGI

(click the picture for the shop)

awnings at 23℃ and 70℃. The modulus of elasticity and the initial slope of the curves for awnings made from PENGI were three times greater than those for polypropylene fabrics; this indicates that the deformation of polypropylene awnings is three times greater than that of PENGI awnings.

Creep tests showed that the final elongation of polypropylene awnings was three times that of PENGI at 23°C and twice that of PENGI awnings at 70°C.

After removing the load, the residual deformation of the PENGI awning after 24 hours was lower than that of the polypropylene awning, as shown in Fig. 6.

From the test results of light and weathering resistance of PENGI, the strength of various colors of PENGI remained basically unchanged after nearly 400h of aging test, while the strength of polyester fabrics decreased by about 50%.

(click the picture for the shop)

In summary, PENGI has the following points:

1. Excellent color fastness to light and weathering.

2. Fabrics have sufficient strength for outdoor use.

3. Resistant to degradation by UV light.

4. Good resistance to mildew, chlorine, and other chemicals, bright colors, and a full-color spectrum.

5. Can be used on all types of weaving and knitting equipment.

6. Produces fabrics with good sewability and good dimensional stability.

-7.png?w=800&h=800)

-7.png?w=800&h=800)